Today's circuits are like small boats swimming in a sea of electromagnetic (EM) energy that fluctuates widely in intensity and frequency. Electromagnetic interference (EMI), radio frequency interference (RFI), often grouped under the subject of electromagnetic compatibility (EMC), are ubiquitous and related phenomena that can affect the performance of circuits and official product compliance approval. While these issues have been a concern since the early days of electronics, the challenges they pose have become increasingly difficult due to the proliferation of wireless connectivity and the use of higher frequencies, more sensitive circuits, and lower voltage rails.

Interference affecting circuits may be caused by nearby intentional and unintentional transmitters of electromagnetic energy, or may be caused by natural or man-made sources. The circuit itself may also emit undesirable or unacceptable electromagnetic energy, affecting nearby electronic equipment. The most common solution to mitigate EMI/RFI energy issues is to add shielding around critical components of the circuit board or even the entire module. During the breadboard and prototype stages, this shielding can provide temporary insight into the problem, mitigate it, and resolve it. However, this ad hoc solution is not compatible with manufacturing environments, or with testing, debugging and repair stations.

This article identifies fundamental EMC challenges for printed circuit boards, components and products. Harwin's off-the-shelf shielding solutions are then explored and how they can be used to improve technical effectiveness and production compatibility.

There are two ways to cause EMC problems

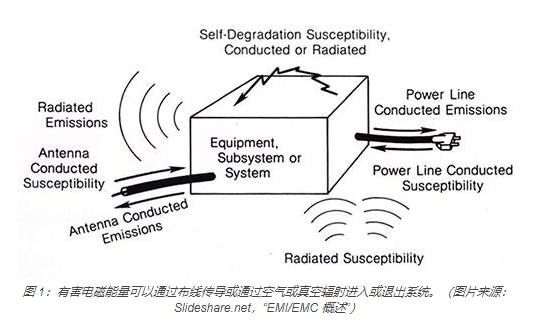

Electrical interference energy can be transferred from the source to the "victim" circuit by conduction or radiation (Figure 1). In the case of conduction, energy travels through conductors such as wires or cables. Designers often use ferrite beads, filters, chokes, and other passive components to attenuate this energy. In the case of radiation, the energy path is through air or vacuum from source to victim, with no metallic conductors.

These harmful effects can sometimes be reduced by relocating components at the source or victim, but this is a time-consuming process that is often impractical, impossible, or ineffective. Likewise, filtering is not a viable option because most of the interfering EMI/RFI energy is within the relevant operating radio frequency (RF) band, and filtering can reduce the strength of the desired signal and impact system performance.

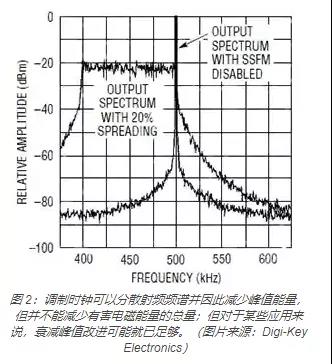

For some radiated EMI situations, a technique called "spread spectrum" is sometimes used to reduce the peak EMI emissions at the operating frequency. In this method, the circuit's clock randomly "jitters" around its nominal frequency as a form of frequency hopping. This spreads the RF energy across the spectrum, but it does not reduce the overall transmitted energy

The spread spectrum method is considered by some designers to be a "cheating" because it is done mainly to meet radiation restrictions, while other designers believe that it is a simple and effective solution. This approach is mainly suitable for DC-DC switching regulators where fixed operating frequency is not important; but for many situations where carrier and operating frequency stability is critical, spread spectrum frequency hopping is not suitable.

Passive shielding: often the solution

In most EMC situations, interfering energy circuitry is beyond the control of the designer, but it must be curtailed at the source or victim. An effective and widely used solution for dealing with radiated EMI/RFI is to add a grounded metal shield around the source of the interfering energy or the victim, depending on the situation. This creates two engineering issues:

Which areas of the PCB need to be shielded?

How should this shielding be implemented in a production environment to minimize time to market, cost, and impact on production?

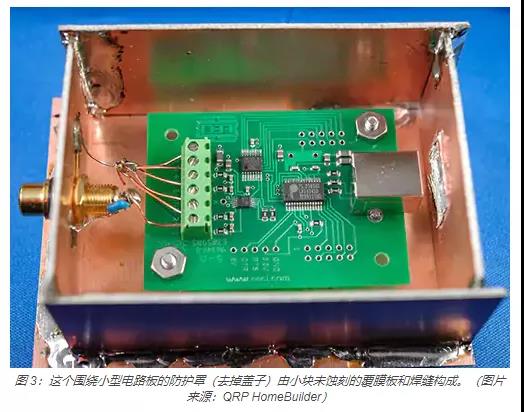

In many cases, the area that needs shielding is obvious, such as the RF transceiver section; in other cases, finding the portion of the circuit that emits or is susceptible to excessive EMI/RFI requires Work twice as hard. To find these areas, designers typically build a small EMI-enclosed conductive box that encloses and shields the area under investigation. Depending on the product and design, the box may need to be as small as a fingernail or large enough to surround the entire printed circuit board.

For smaller RF enclosures, thin copper sheets can be used to fold into boxes, and the seams can be welded or covered with copper tape with conductive glue. For medium and large enclosures, you can cut a scrap copper-clad printed circuit board to the required size and then solder or tape all the seams together with conductive tape. In some cases, the joints are "positioned" first to ensure basic stability, and then covered with conductive tape.

The box is then placed over the area of the circuit board to be evaluated and the seam line between the open bottom and the PCB is soldered to a low impedance RF ground line. In practice, this can be more challenging than it seems because the printed circuit board often does not yet have a corresponding ground trace around the perimeter of the tank being built. While a few connection points may be sufficient, a more continuous ground seam means there will be fewer RF leakage paths into or out of the tank assembly.

There is another problem with this welding method. Since many PCBs have very thin copper cladding, soldering or desoldering the test jar to the board will most likely damage the delicate copper cladding and damage the board. Therefore, before building and gluing these shielded cans, it's a good idea to take some measurements of the situation using RF probes and sniffers.

A better way to shield prototypes

It is possible to create a shielded can using copper foil or copper-clad printed circuit boards, but it is a time-consuming process. There's also the FR-4 substrate to handle (if using PCBs), which is difficult to cut without the proper gear and can leave nasty fiberglass "shards" on your fingers unless you wear gloves. Even using bare copper can be problematic, as you can cut your fingers if not handled carefully, and a small bending machine may be required to perform 90° bends on edges and corners. This DIY method for making your own shielding test box may seem simple at first, but it's not as quick and easy as it looks, although it certainly does work.

Consider RF attenuation and cooling factors

A fundamental practical problem with placing solid-surface metal cans around circuit components is that they impede convective cooling airflow over the surrounding component surfaces. It may seem that in many applications the use of shielded cans should be ruled out, but this is not the case. The reason is that the metal shell of the can is quite thin, ranging from 0.15 to 0.3 mm depending on the specific model and specification of the can. This thickness creates only a small obstacle to the conduction of heat from the inside of the jar to the outside. Once the heat reaches the outer surface of the can, it can be dissipated through natural or forced air convection or other means.

In this regard, thin metal cans perform much better thermally than shielded enclosures made of ordinary FR-4 PCB material. The latter has a thermal conductivity between 1 and 3 Watts/meter-Kelvin (W/m-K) and a standard thickness of 1.6 mm, so the thermal resistance is much higher. Compare this number to the thermal conductivity of nickel silver, which is about 1000 times more conductive and much thinner (only 0.15 to 0.3 mm). The effect of thin metal cans on cooling can be quantified through basic thermal modeling. Alternatively, standard techniques can be used to take advantage of the high thermal conductivity of the underlying printed circuit board copper to remove large amounts of heat from the mounted components. This is a good practice in almost all situations.

An obvious solution to improve heat convection in a shielded tank is to make holes in the surface of the tank. However, this adds a new problem to Product

. The holes must be small enough and spaced far enough apart, otherwise there may be radio frequency leakage. Since the maximum allowable diameter and spacing are a function of wavelength, the most straightforward requirement is that any opening must not exceed one-tenth of the shortest wavelength of the RF being shielded.Determining critical wavelength and hole size is not always easy or obvious, however, because the frequency of interfering RF energy may be higher (and therefore shorter wavelength) than the product's apparent operating frequency or carrier frequency. Given that interfering gigahertz frequency signals can overload and saturate nearby megahertz frequency front-end amplifiers, the maximum allowable aperture must be much smaller than a simple preliminary analysis of the product's operating frequency would determine.

Remember that in addition to ensuring circuit performance, another goal of shielding cans and clamps may be to provide RF attenuation over a wide frequency range to meet regulatory requirements for the product. These EMC-related regulatory standards define the maximum RFI/EMI that a product can generate in various regions of the radio frequency spectrum, as well as the permissible susceptibility of a product to being an EMI/RFI victim, regardless of the nominal operating frequency.

Thus, shielding must typically not only guarantee performance at the apparent operating frequency, but must also provide attenuation across the broader EM spectrum. Using cooling holes sized only for the nominal operating frequency may reduce the attenuation of those shorter wavelength spectrum and may affect regulatory approval.

Conclusion

Electromagnetic compatibility and RFI/EMI issues affect nearly all electronic products and applications, and the increasing use of higher frequency wireless links makes design even more challenging. Radiated EMI/RFI causes many problems, and the solution often involves basic RF shielding, which involves using a metal can to completely enclose the affected circuit.

These cans are available as standard in a variety of sizes and with PCB clamps in various configurations to allow the cans to be easily snapped onto or removed from the circuit board. The clamps are also fully compatible with equipment used for inserting and soldering SMT packaged components in volume production environments.